Manufacturing

Manufacturing Process

Step 1

Raw Material

KPC Herbs are manufactured from premium quality raw materials that must pass a series of stringent inspections performed by in-house professional technicians utilizing our state-of-the-art process and precision instruments.

Species Identification

Physical Appearance

Inspecting the physical qualities of raw herbs.

Organoleptic (physical) Inspection.

Microscopic Analysis

Distinguishing herbs based on their microscopic characteristics

Chemical Identification

Using advanced techniques to identify key compounds. Thin Layer Chromatography (qualitative).

Chemical Fingerprinting

Matching the DNA of raw materials to a standard reference. High Performance Liquid Chromatography (quantitative).

Heavy Metal / Pesticide Inspection

- UPLC-ICP-MS – Heavy Metal

- UPLC-MS/MS – Pesticides

- GS-MS/MS – Pesticides

Chemical Analysis

- The herbs are analyzed for its moisture content, purity, extraction and other properties.

- Only upon passing the above inspections for quality, identity and safety, may the herb material be accepted into our facility for further processing.

- KP leads the industry in the breadth and comprehensiveness in herbal identification/inspection technologies and techniques.

Step 2

Preparation & Verification

Once accepted, the herbs go through a meticulous cleaning until dirt and foreign materials are removed. It then goes through a process known as “paozhi”, done in accordance to specified methods unique to each specific herb where necessary. We pride ourselves in our commitment in adherence to traditional methods, for example, there are instances such as when herbs are to be input into a formula decoction at specified stages, rather than all at once. In addition, KPC formulas are extracted homogeneously, which provides for the superior synergistic effects which cannot be replicated otherwise.

Step 3

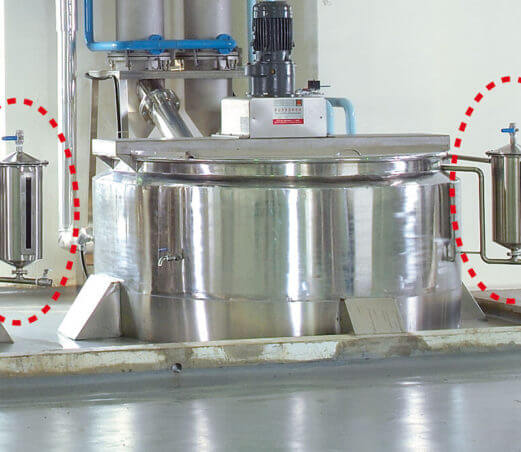

Extraction

The herbs are placed in a rotary extractor which spins to mix the herbs in a decoction liquid while the temperature is increased to cook the herbs. The precise extraction temperature and timing is strictly controlled to maximize efficiency and thoroughness.

Step E

Collection & Restoration of Essential Oil

KPC’s extraction employs a patented essential oil restoration and collection process, allowing the vat to capture and preserve the volatile oils, which are reintroduced when the herbs are in the granulation phase. Essential oils increase efficacy and infuse the herbs with their natural aromatic properties. This is what provides KPC granules the edge over our competitors.

Step 4

Herbal Concentration

The extracts in liquid form flows through a pipeline directly into a state-of-the-art concentration system. The liquid gradually condenses through low temperature evaporation. The low-temperature preserves the potency of the herbal extract potency that would otherwise be damaged under extended exposure to high temperatures.

The duration is adjusted until the best herb-to-solute ratio is ascertained. Because each herb/formula have a different optimal herb extraction ratio. Optimal Extraction is what KP consistently strives for.

Step 5

Granulation

The concentrate, now in the form of a viscous paste, is piped into a flow coater. The concentrated paste is sprayed onto minute particles of a base material as the moisture slowly dissipates. The flow-coater’s process is automated, and it is completely sealed off to prevent the possibility of cross-contamination. The base material is formed using non-GMO potato starch and/or ground herbs depending on the formulation. With the moisture evaporated, the result is a fine, free flowing extract granule that is now ready to be packaged, or further processed into easy-to-swallow tablets or capsules.

Step 6

Packaging & Appearances

Like all plant products, the characteristics of herbs vary from season to season and year to year depending on the environment in which the herbs were picked. Naturally, it is normal for the resulting granules to vary slightly in color, texture or aroma, reflecting the variations in the source herbs from which they were produced. KPC’s herb granule extracts are produced in batches with each batch assigned a unique lot number, which can be found in the bottom corner of the bottle’s label.

Step 7

Final Inspection

KPC’s in house ISO 17025 laboratories will analysis multiple samples from each production lot to measure the quality, safety and efficacy of the product, employing the state of the art precision instruments and methods against:

These tests include the following:

- HPLC- Marker ingredient analysis and verification

- UPLC-ICP-MS – Heavy Metal Analysis

- UPLC-MS/MS and GS-MS/MS – Pesticides Screening (up to 507 pesticide detection capability)

- Microbial screening (E. Coli, Salmonella, Yeast and Mold, etc.)

Upon passing our finished product testing, a Certificate of Analysis (COA) will be issued. The COA documents the excellent quality of our herbal extracts. No batches of products will leave the KP manufacturing facility without a COA that proves that the strict standards of KPC has been achieved.

The KPC Standard is a collection of the strictest criteria from Taiwan, Singapore, Israel, Australia, U.S., and the E.U. Modern scientific processing methods and rigorous quality control sets KPC apart from other sources of herbal extracts, allowing KPC Herbs to pass rigorous international standards and be distributed and consumed safely across the world, making us truly world-class.